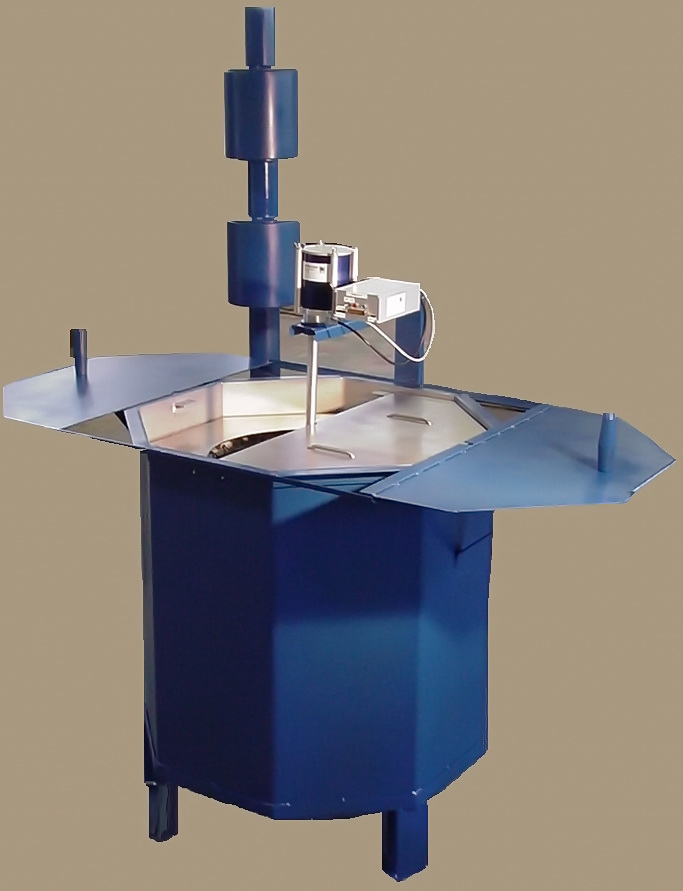

Furnaces and heating arrangements

for laboratory and pilot plant

for laboratory and pilot plant

HTM Reetz heating systems and high-temperature furnaces for laboratory and pilot plant applications are used in a wide variety of applications. Our experienced staff will be pleased to advise you on special questions.

1. High temperature chemistry

- High temperature synthesis under defined gas atmospheres

- Pyrolysis of organic compounds

- Calcination of precursor compounds

- Solid state reactions at elevated temperature

- Molten salt chemistry

- High temperature corrosion

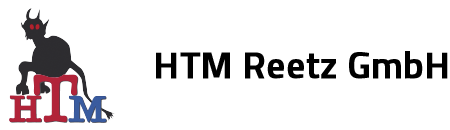

A wide variety of furnace types and special constructions are used for this work. Which furnace is used for which special application depends on the requirements of the material system and quantity, the required temperatures and the gas atmosphere. For small sample quantities in annealing boats, tube furnaces of the type LOBA, LORA and split tube furnaces have proved particularly suitable, while rotary furnaces have proven themselves for larger sample quantities and the modeling of technical processes.

2. Chemical transport reactions

- Thermo chromatography in temperature gradient with reactive gases

- Gas transport processes

- Crystal growth from the gas phase

3. Metallurgical processes

- Reductive treatment of metal powders for oxide removal in protective gas furnaces

- Reductive treatment of metal powders for oxide removal in protective gas furnaces

- Active metal brazing of ceramic-metal and ceramic-ceramic joints in special high-temperature high-vacuum furnaces or quartz glass furrnaces

- Corrosion in molten metals in crucible furnaces mainly in closed ampoules

- Homogeneous annealing and phase adjustment in tube furnaces or cold wall furnaces

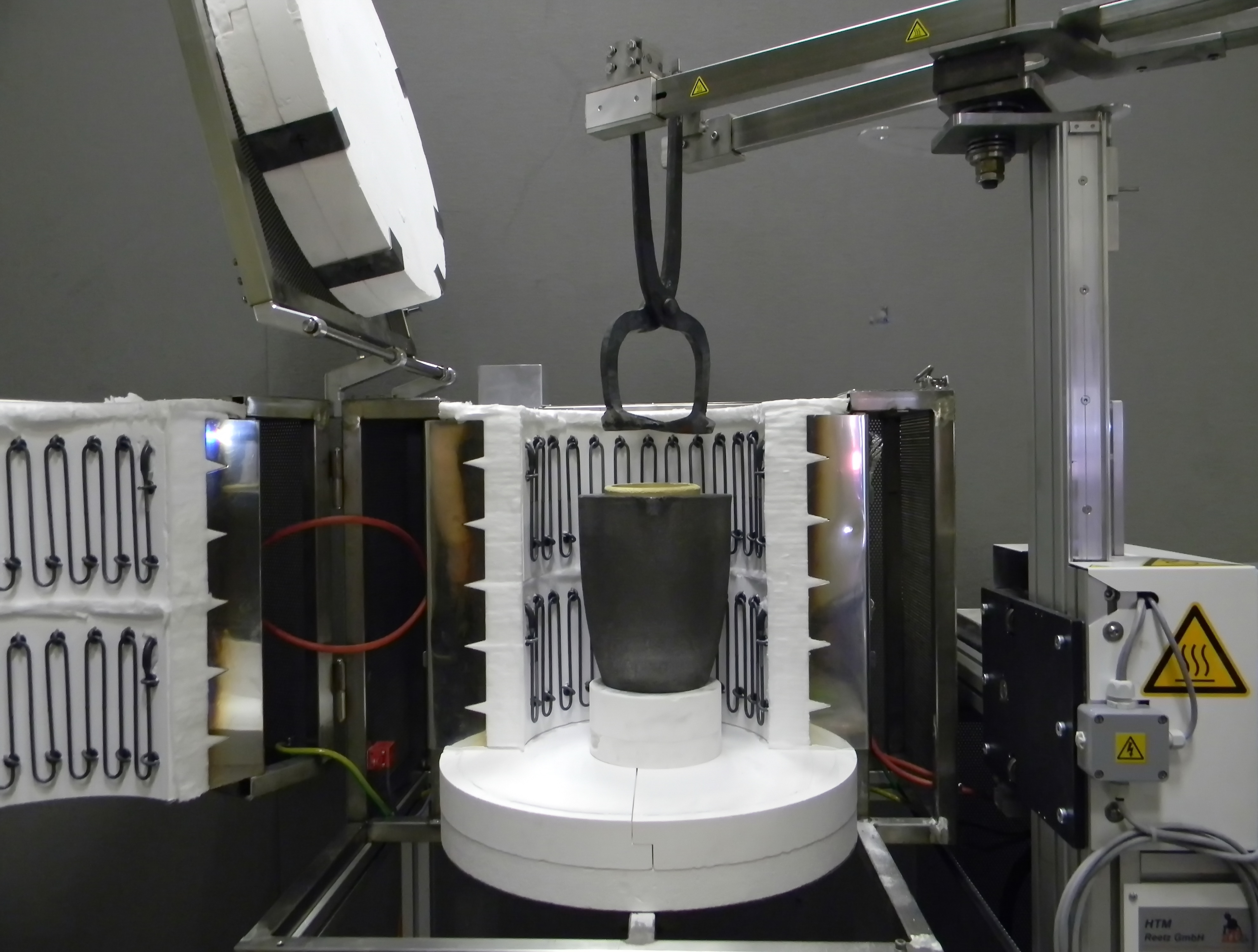

4. Powder metallurgy and ceramics

- Powder synthesis of non-oxides

- Setting of defined stoichiometries by gas-solid reactions

- Thermal powder treatment

- Debinding

- Sintering of oxides and non-oxides

- Graphitizing

- Thermal etching

- Thermal afterburning

According to your ideas, the entire range of furnace technology can be used for these applications, naturally taking into account the desired temperatures and other requirements.

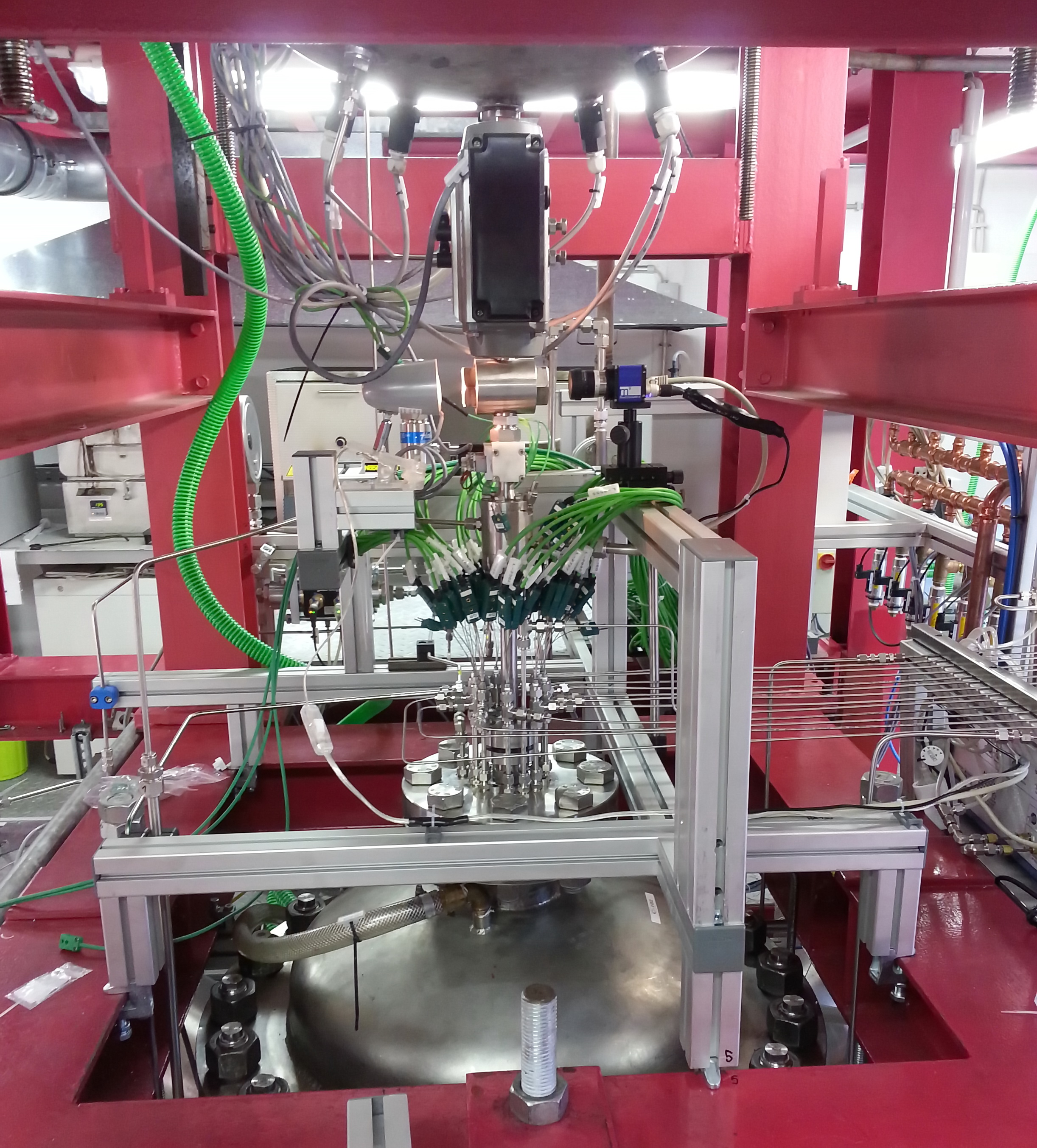

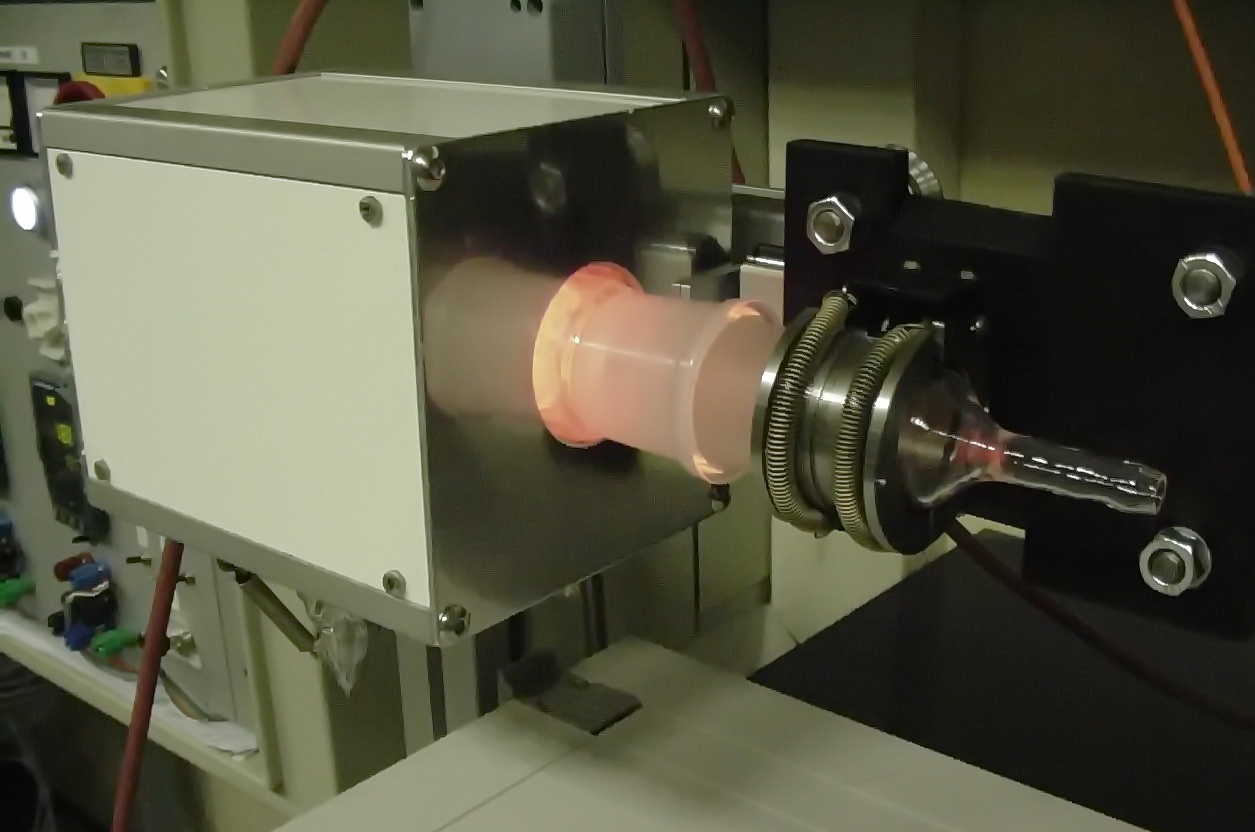

5. Nuclear and isotope technology

- Modelling of VVER Incore Melting with a gas-fired arrangement up to 2200 °C

- Separation of volatile fission products from UO2 like 99Mo

- Packing of 14C waste

- 131J separation

If you intend to use furnaces for radioactive work, the radiation protection regulations must be taken into account. We would be pleased to work out a corresponding special solution in close cooperation with you.

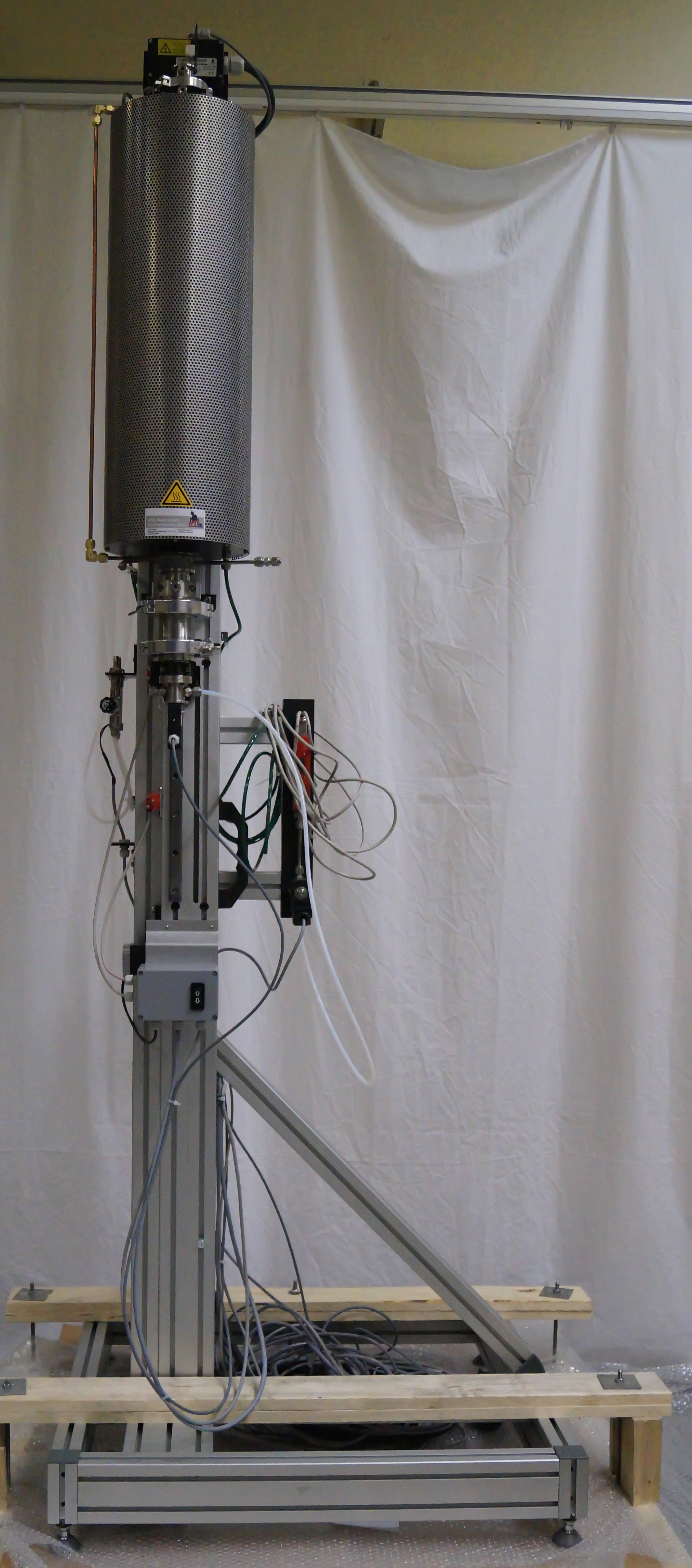

6. Physical-thermal examinations

- Evaporation of volatile products from solids and liquids

- Diffusion processes in the solid state

- Thermogravimetry

- Thermodiffusion

- Thermal chromatography

If you are interested in the viscosity of slags at high temperatures, if you need information on diffusion processes in solids or if you are interested in melting points or other temperature-dependent chemical parameters, we have an extensive range of furnaces available for you.

7. Crystal growing

- Crystal growth from the gas phase in mostly multi-zone tube furnaces

- If the samples are enclosed in ampoules, crucible furnaces and glovebox furnaces are also used

- Crystal growth using the Tammann-Stöber method and the Bridgman-Stockberger method

8. Energy and environmental technology

- Top-hat furnaces for SOFC stacks

- Modelling of solar hydrogen production

- Gasification of coal and biomass

- Investigation of the effectiveness of exhaust gas catalytic converters

- Thermocouple calibration

- Gas heater

- Catalyst test furnaces

Here, too, the entire range of furnace technology from HTM Reetz is at your disposal to meet your criteria for material system, material quantity and required temperatures.