Split tube furnaces

Split tube furnaces allow the heating of objects that do not fit through a smooth tube due to their geometry. Examples are reactors with firmly welded flanges at the tube ends, radial accesses for observations in the furnace chamber or curved tubes. Furthermore, the use of split tube furnaces can accelerate the cooling of the samples.

HTM REETZ offers split tube furnaces with different heaters, with a wide range of working chamber diameters and lengths as well as different possibilities of furnace mounting. The furnaces are complemented by a wide range of control units adapted to the application requirements, with and without PC interfaces and software for program and gas control.

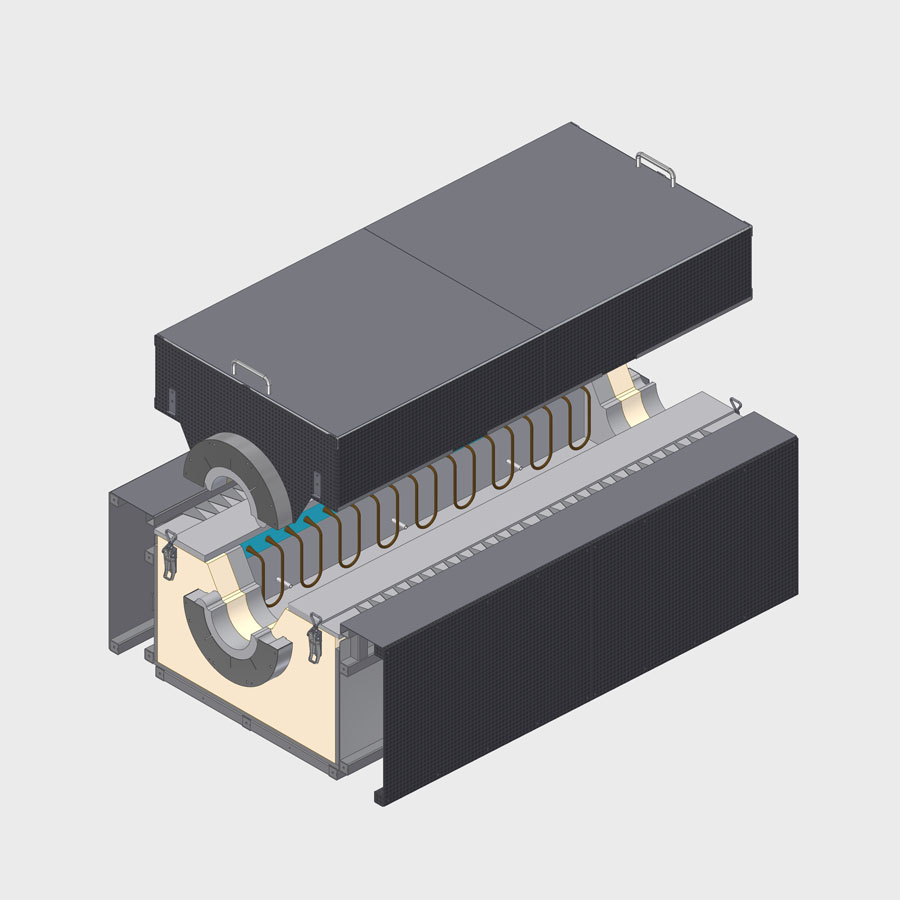

Split tube furnaces LK-H

(Laboratory split tube furnace (Klappofen in German) with Heating wire windings)

This versatile furnace type is characterized by its working chamber that can be opened along the longitudinal axis. Due to the maximum temperature of 1150 °C, it is ideally suited for use with gas- or vacuum-tight quartz working tubes. Numerous possibilities – such as different frame variants, designs as multi-zoned furnace or gas-tight installations – make it an all-round talent.

Short description:

- Temperatures up to 1150 °C

- Atmospheres: oxidizing, reducing, inert and vacuum (depending on material and wall thickness of the heated reactor)

- Heated diameter: 8 to 350 mm

- Heated length: 20 to 5000 mm

- Control unit separated from the furnace

- Power range 100 W to 36 kW

- Wall temperature up to 100 °C

Heating system:

- Single-zoned

- Multi-zoned

Applications:

- Heating unit for rotary furnaces

- Heating unit for cat test furnaces

- Heating of reactors (normal pressure, high pressure, vacuum)

- Fibre treatment

- Heating in pipe systems

- Heating of test apparatus, e.g. for fuel cells and

samples in towing devices

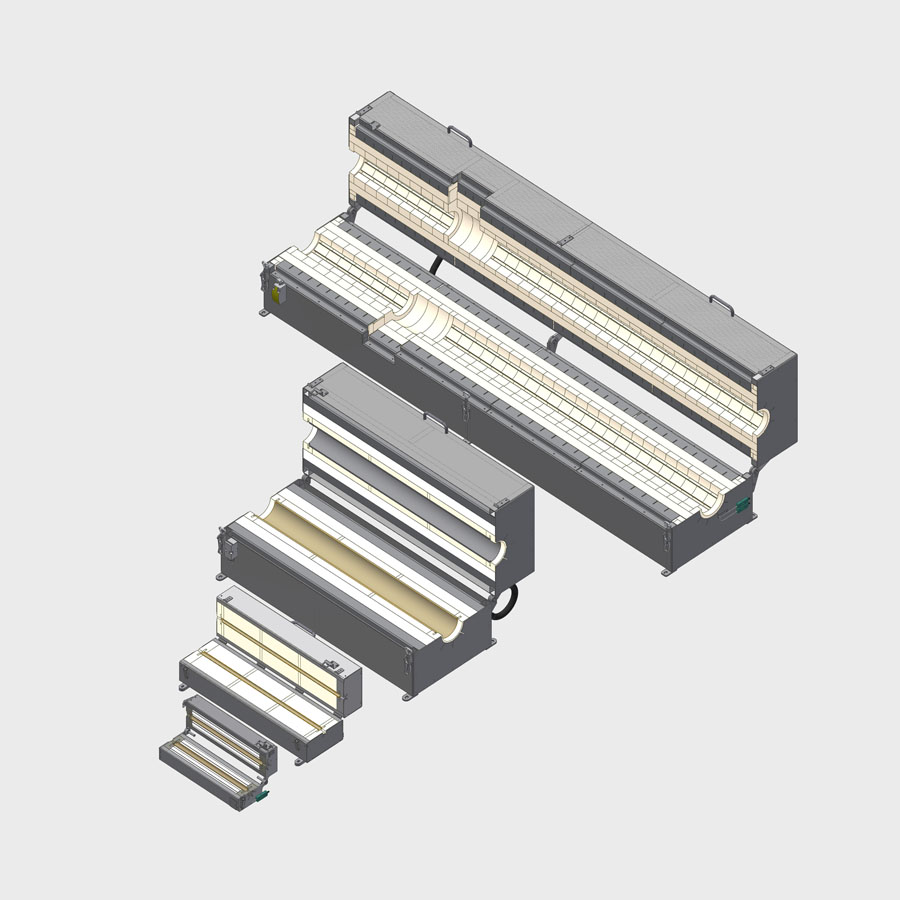

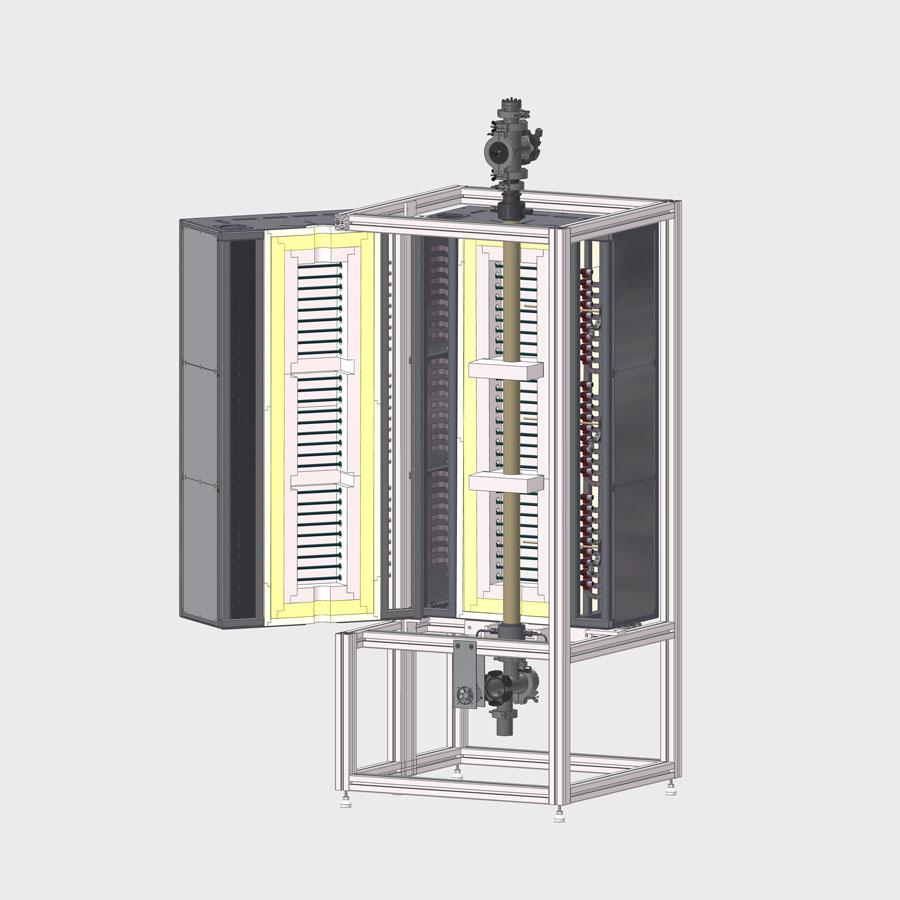

Split tube furnaces LK-S

(Laboratory split tube furnace (Klappofen in German) with SiC elements)

This split tube furnace with SiC heating elements is particularly suitable as a heating unit for complex devices such as reactor heating or as a base for rotary furnaces. It is particularly characterized by the variable design of the working chamber to be heated. In particular, it meets customer requirements when working temperatures in the range up to 1500 °C are required without additional inert gas flushing of the heating conductor.

Short description:

- Temperatures up to 1500 °C

- Atmospheres: oxidizing, reducing, inert and vacuum (depending on material and wall thickness of the heated reactor)

- Heated diameter: 100 to 350 mm

- Heated length: 300 to 2000 mm

- Control unit separated from furnace

- Power range up to 36 kW

- Wall temperature up to 100 °C

Heating system:

- Single-zoned

- Multi-zoned

Applications:

- Heating unit for rotary furnaces

- Heating unit for falling film reactors

- Heating of analytical equipment (spectroscopic investigations of hot gases)

- Fibre treatment

- Heating of test apparatus, e.g. for fuel cells and samples in towing devices

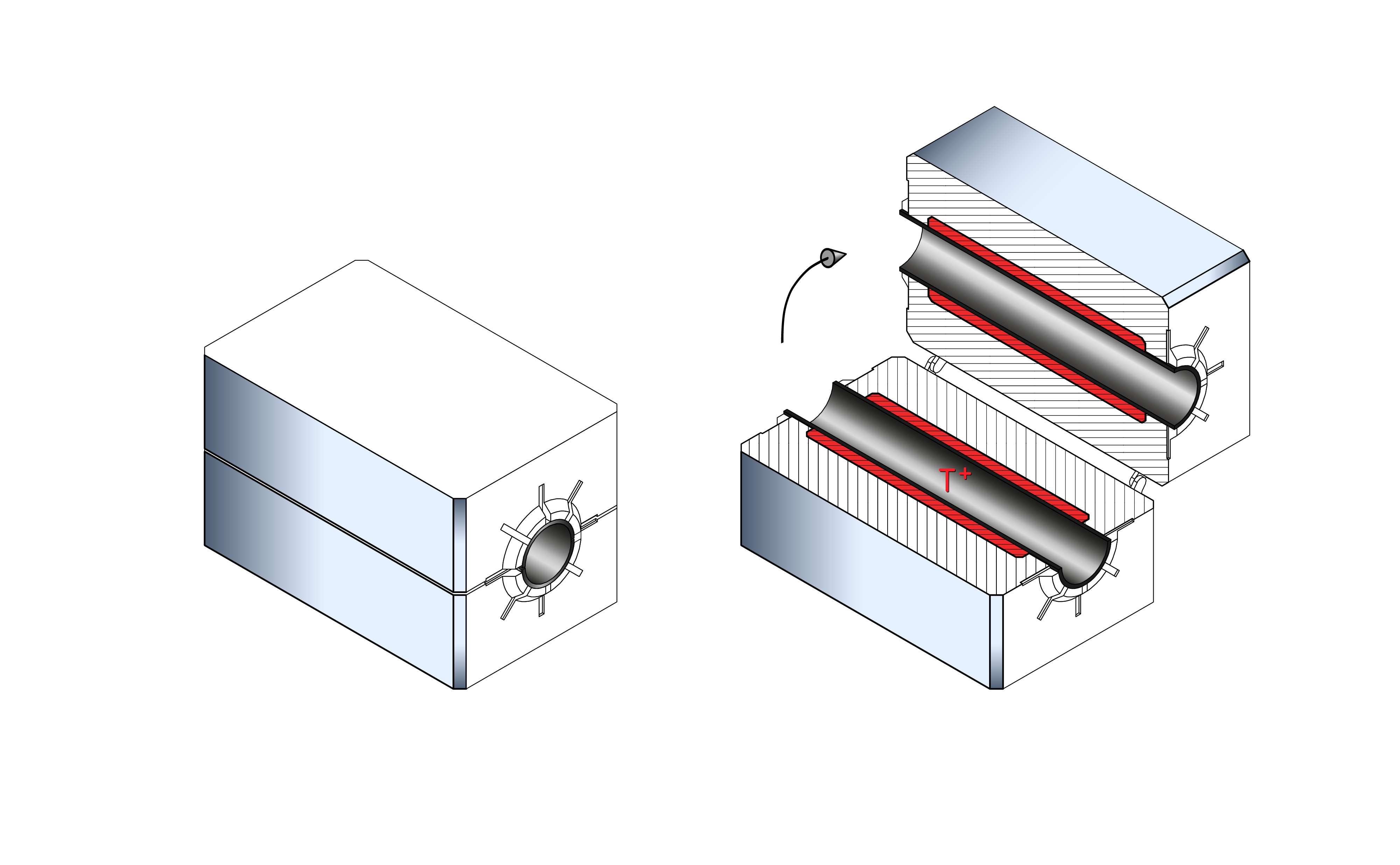

Split tube furnaces LK-M

(Laboratory split tube furnace (Klappofen in German) with Molybdenum disilicide)

This split tube furnace is equipped with heating elements made of molybdenum disilicide (MoSi2), which are characterized by a very high element temperature of 1725 °C, high heating speeds and long service life. It is ideally suited for heating Al2O3 working tubes in vertical working position.

Short description:

- Temperatures up to 1800 °C

- Atmospheres: oxidizing, reducing, inert and vacuum (depending on material and wall thickness of the heated reactor)

- Heated diameter: 100 to 350 mm

- Heated length: 300 to 2000 mm

- Control unit separated from furnace

- Power range up to 36 kW

- Wall temperature up to 100 °C

- Restrictions: The working position of this folding variant is not variable. The furnace can only be used in one working position at a time.

Heating system:

- Single-zoned

- Multi-zoned

Applications:

- Heating unit for rotary furnaces

- Heating unit for falling film reactors

- Heating of analytical equipment (spectroscopic investigations of hot gases)

- Fibre treatment

- Heating of test apparatus, e.g. for fuel cells and samples in towing devices