Tube furnaces

Tube furnaces are mainly used because their cylindrical working space enables the samples to be heated on all sides, uniform gas supply, and they are stable against external and internal pressure. They are space-saving and can be adapted to individual customer requirements in a variety of ways.

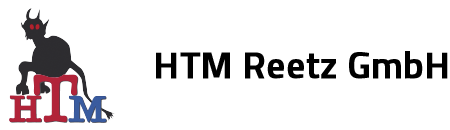

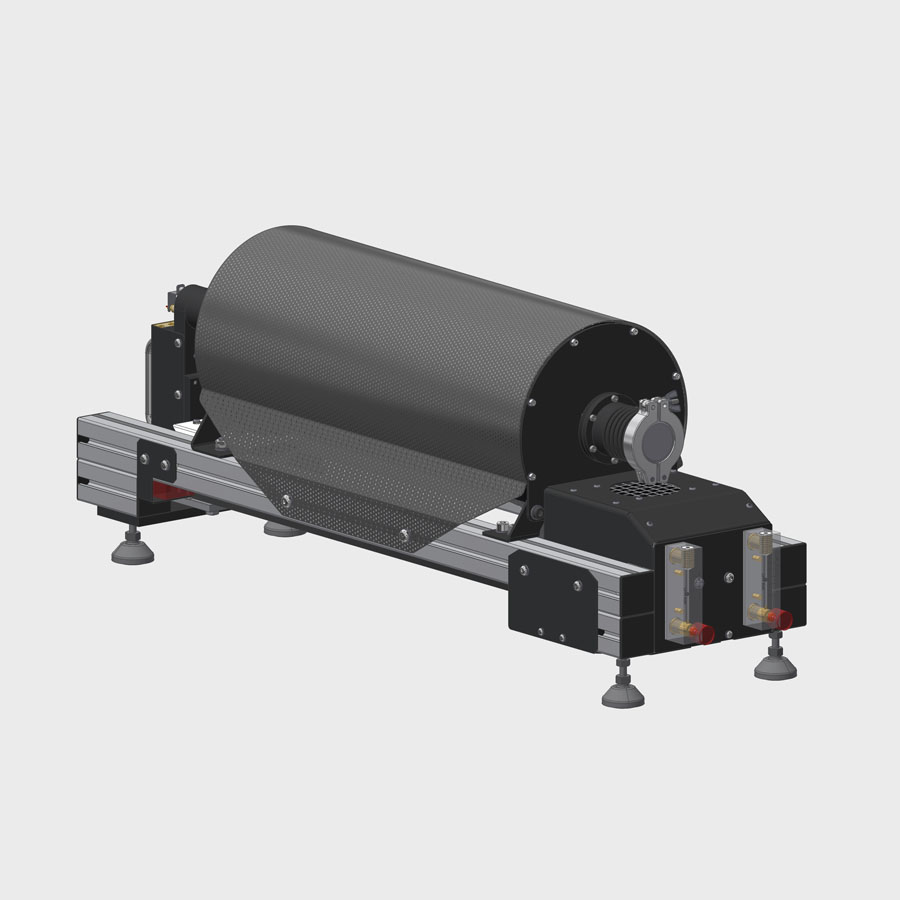

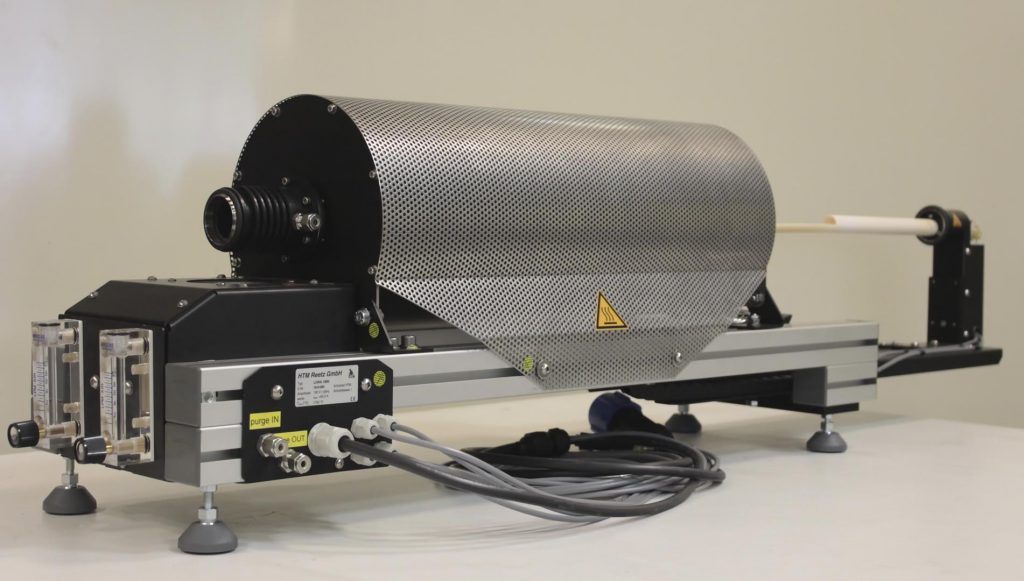

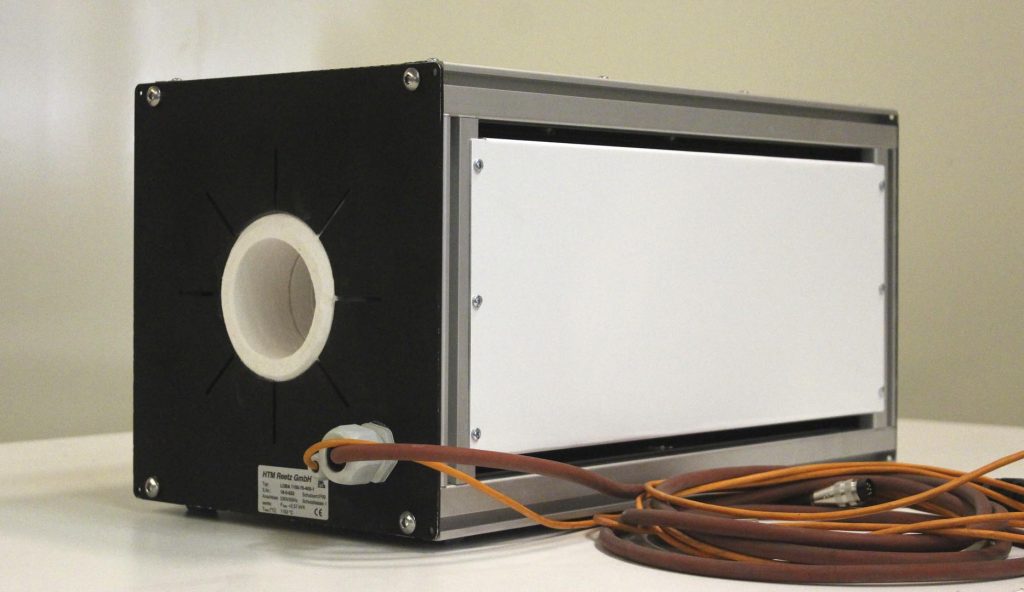

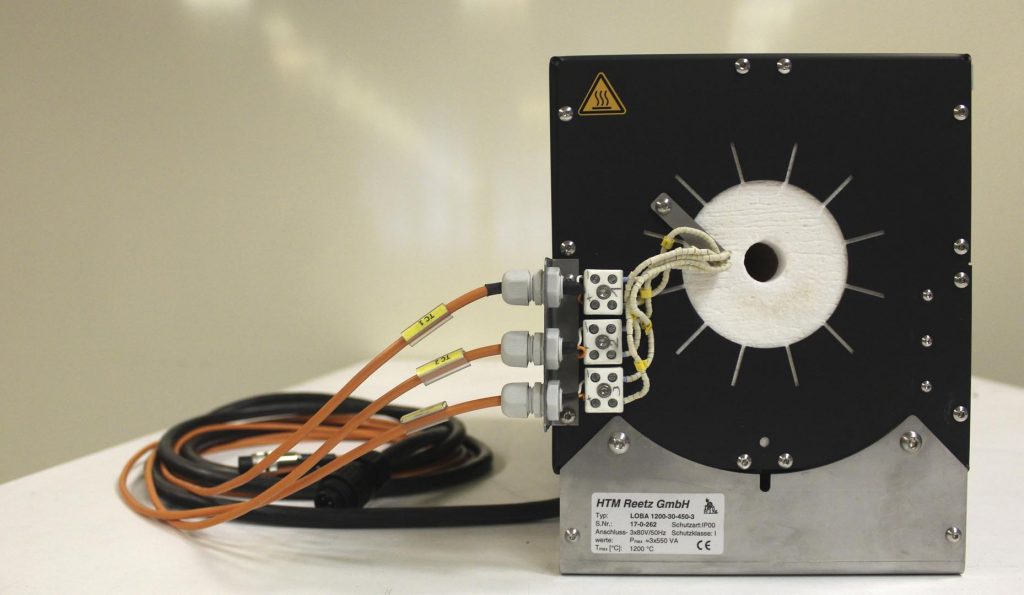

Tube furnace type LOBA

(Laboratory Oven/Furnace for Broad Applications)

A characteristic feature of the LOBA tube furnace is its simple and robust construction with many design and equipment variants. It is versatile and can be operated vertically, inclined and swivelled. In addition, it has adaptable fastening options that allow it to be integrated into larger devices. This furnace type is also stackable. Different materials are available for insulation, if required and agreed upon, also those which are free of aluminium silicate fibres.

Short description:

- Temperatures up to 1200 °C

- Atmospheres: oxidizing, reducing, inert and vacuum

- Tube diameter: 4 to approx. 250 mm

- Heated length: 10 to 1500 mm

- Control unit separated from furnace

- Integratable in complex devices

- Power range up to maximum 3 x 12 kW

Heating system:

- Single-zoned

- Multi-zoned

- Dual zone for adjustable gradients

- Gradients determined by heating coil

Equipment features:

- Frame for holding the furnace in different working positions

- Insert working tube with gas-tight end caps (for working in defined atmospheres and vacuum)

- Sample thermocouples

- Viewing window

- Charging systems

- Dropping devices

- Weighing device

- Crucibles and boats

- Gas supply units

- Afterburner

- Wide range of control units with and without PC interfaces

- Software for program and gas control

Applications:

- Melting

- Calcination

- Pyrolysis

- Debinding

- Sintering

- Degassing

- Vacuum tempering

- Crystal Growing

- Transport tests

- Contact angle measurements

- Fibre treatment

- Physical experiments

- Quenching tests

- Solid state chemical analyses

- Thermochromatography

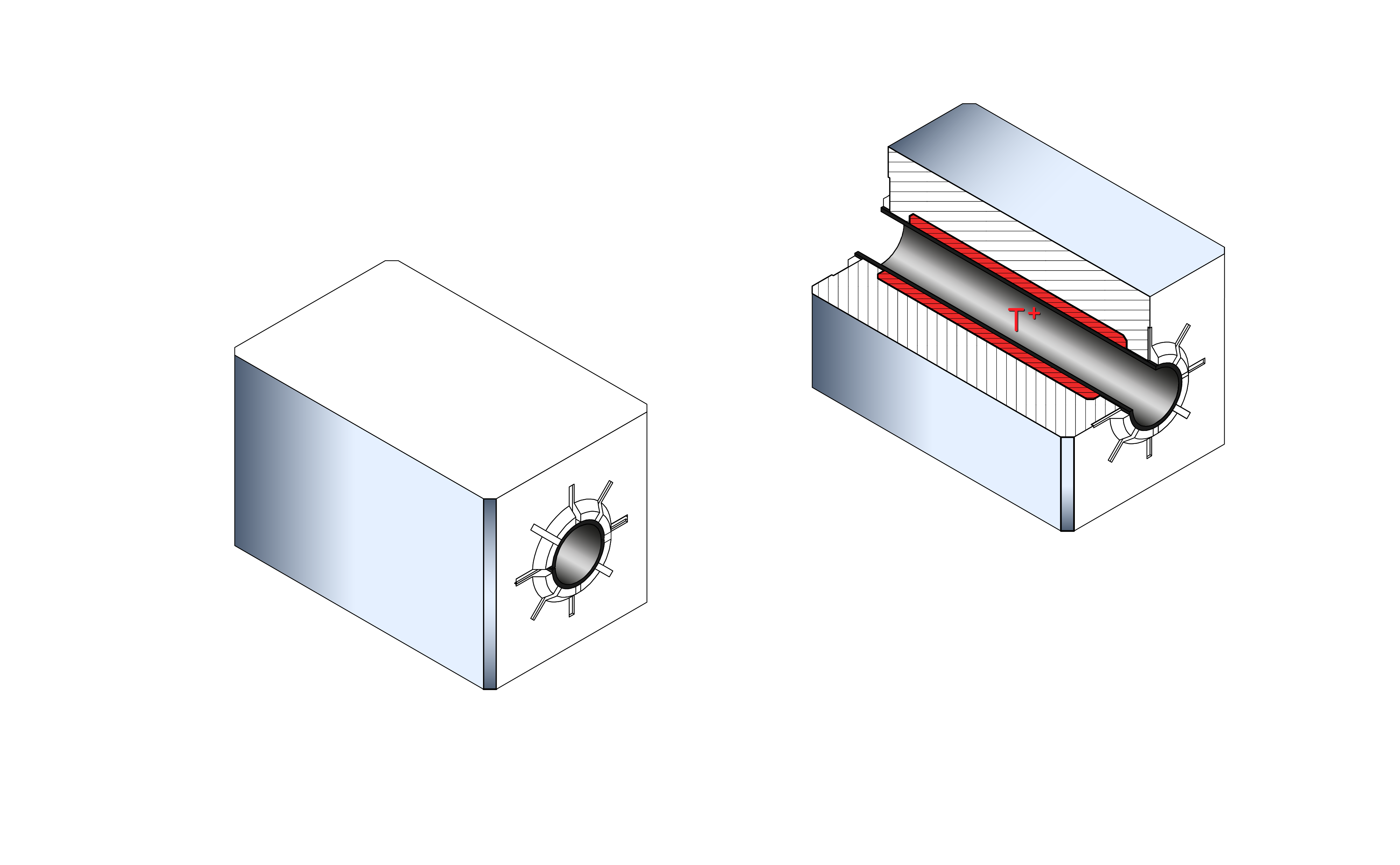

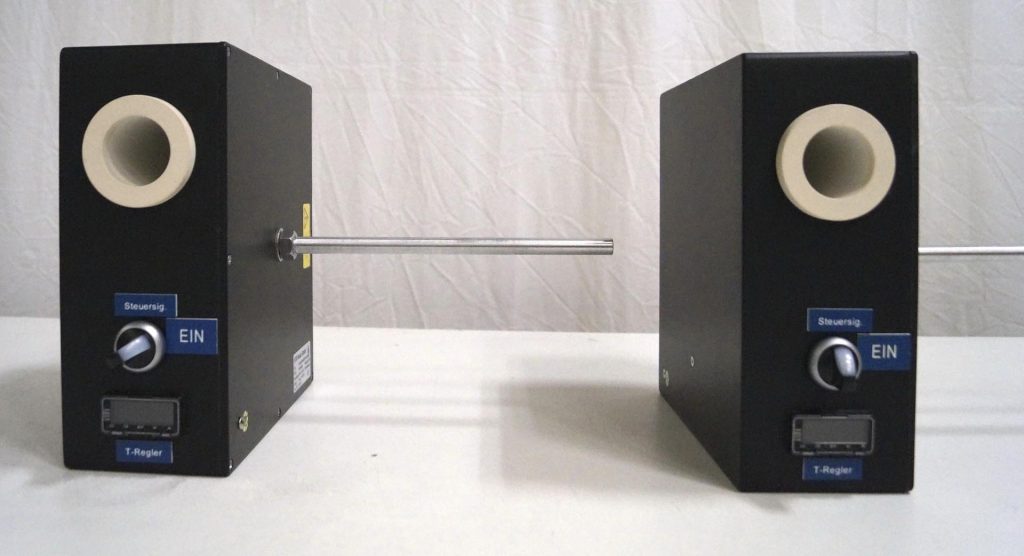

Tube furnace type LOSA

(Laboratory Oven/Furnace for Stand Apparatuses)

Type LOSA is an inexpensive and space-saving tube furnace for chemical laboratories with integrated power supply,

prepared for mounting on tripods.

Short description:

- Temperatures up to 650 °C

- Atmospheres: ambient atmosphere only

- Tube diameter up to approx. 40 mm

- Heated length: 160 mm when closed on one side, 220 mm when open on both sides

- Control unit incorporated in the furnace

- Can be integrated in complex devices

- Power range up to maximum 1 kW

Heating system:

- Single-zoned

Equipment features:

- Crucibles and boats

Applications:

- Melting

- Calcination

- Degassing

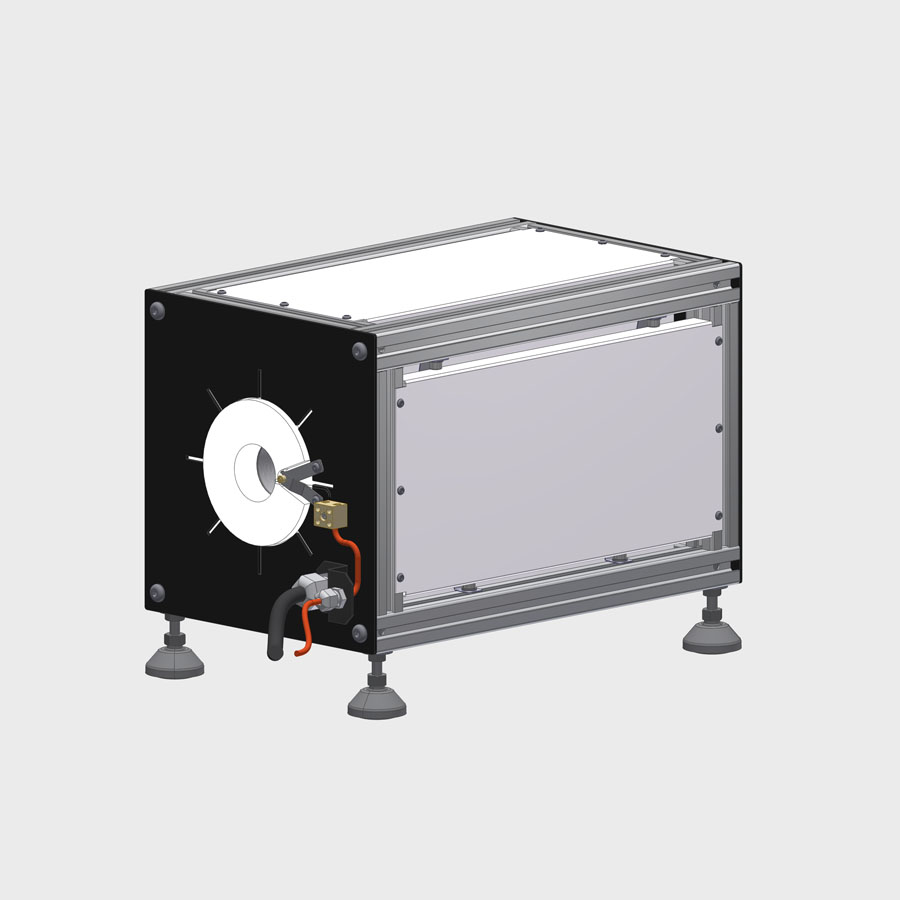

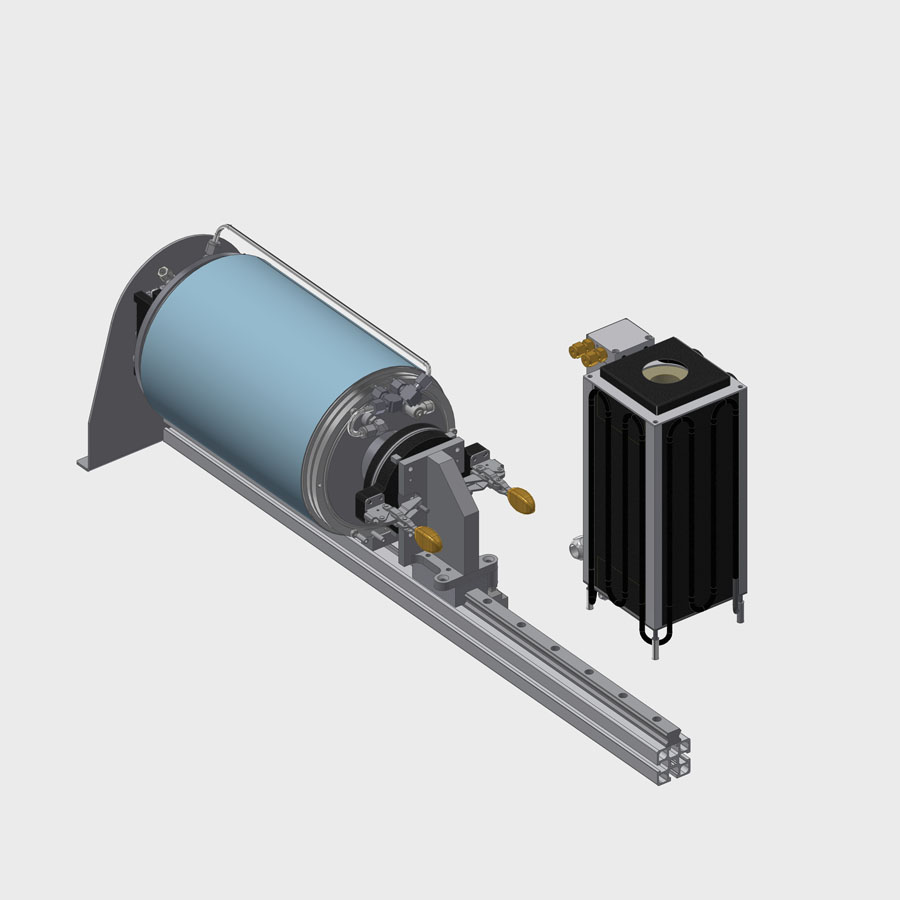

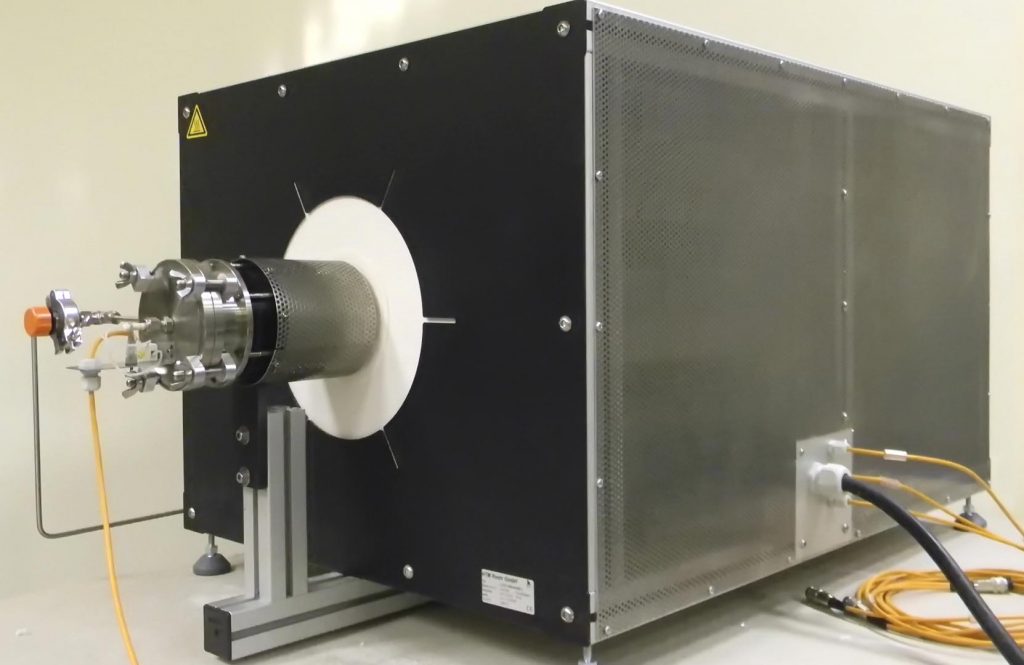

Tube furnace type LORA

(Laboratory Oven/Furnace for Reducing Atmospheres)

This high temperature furnace with working tube accessible from both sides is called type LORA. It is particularly suitable for work in defined atmospheres. It is available in many design and equipment variants. Requirement: The heating conductor chamber must be constantly purged with a small amount of protective gas (< 1 l/min). Special feature: Even at the highest temperatures there is no permeation of oxygen through the tube wall into the working chamber.

Short description:

- Temperatures up to 1750 °C

- Atmospheres: inert, oxidizing and reducing

- Working position: horizontal, vertical and swivel

- Tube diameter: maximum up to 100 mm (optimum 40 mm)

- Heated length: 300 to 1000 mm

- Control unit separated from furnace

- Can be integrated in complex devices

- Power range up to maximum 3 x 6 kW

Heating system:

- Single-zoned

- Multi-zoned

- Gradients determined by heating coil

Equipment features:

- Frame for holding the furnace in different working positions

- Insert working tube with gas-tight end caps (for working in defined atmospheres and vacuum)

- Sample thermocouples

- Viewing window

- Charging systems

- Dropping devices

- Weighing device

- Crucibles and boats

- Gas supply units

- Afterburner

- Wide range of control units with and without PC interfaces

- Software for program and gas control

Applications:

- Melting

- Calcination

- Pyrolysis

- Debinding

- Sintering

- Degassing

- Crystal Growing

- Thermochromatography

- Contact angle measurements

- Fibre treatment

- Vacuum tempering

- Quenching tests

- Investigation of reaction kinetics in downdraft

- Viscosity measurements of melts

- Physical experiments

- Solid state chemical analyses

- Gas chromatography

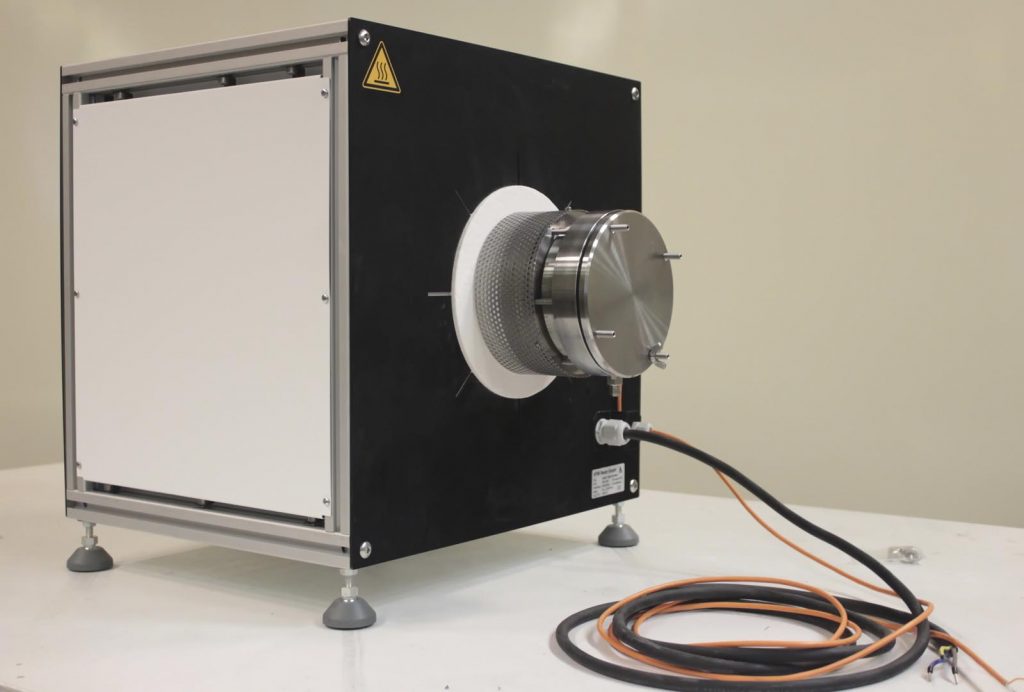

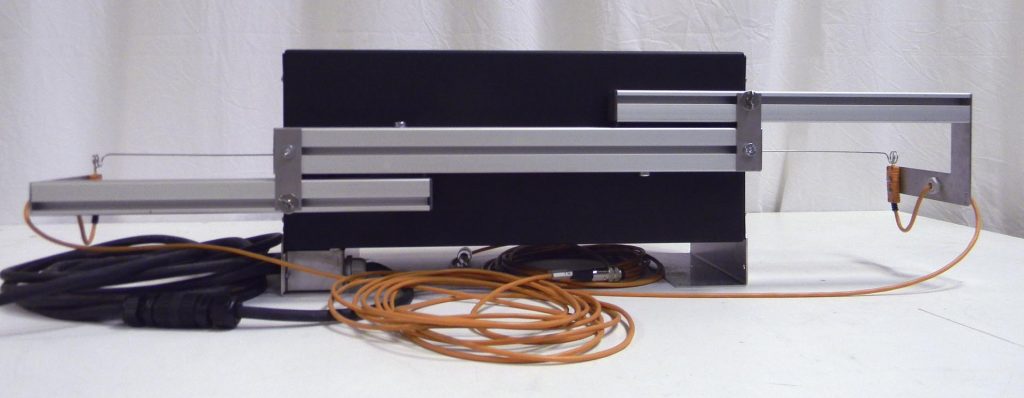

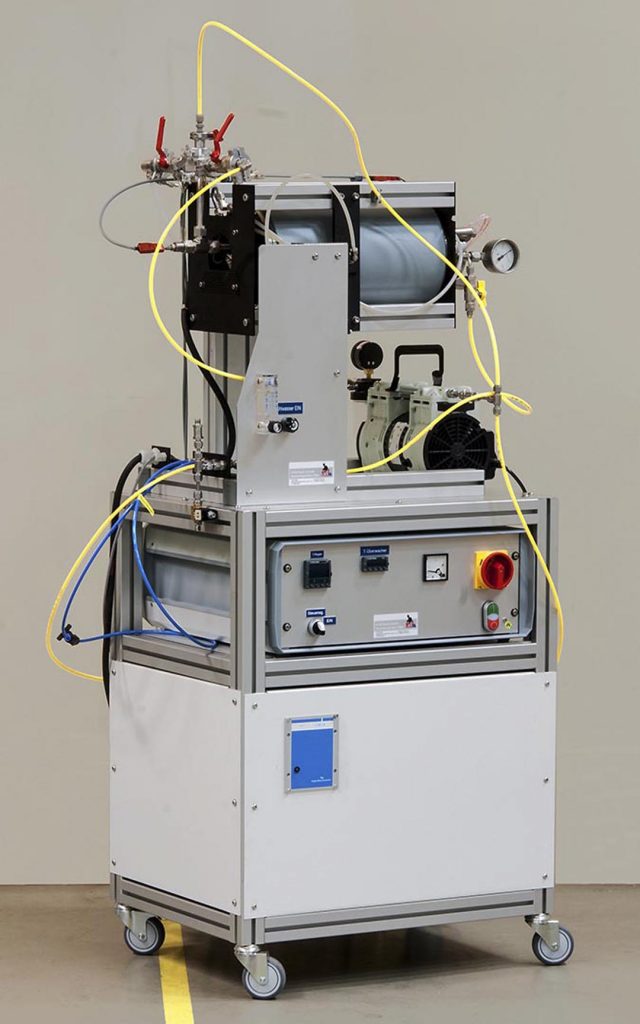

Tube furnace type LORA-G

(Laboratory Oven/Furnace for Reducing Atmospheres – G (Shortcut for word closed in German)

The type LORA-G is a cold wall version of the type LORA and its working tube is only accessible from one side. Due to both characteristics this furnace is suitable for work in combination with gloveboxes. Special feature: It is possible to equip the furnace with an evacuable housing, which allows a very defined setting of the atmosphere in the vicinity of the working chamber. Requirement: The heating conductor chamber must be constantly purged with a small amount of protective gas (< 0.021 l/min).

The furnace can be operated very well in or from gloveboxes. For oxygen-free gloveboxes, the heating conductor compartment can be connected to the glovebox. A separate protective gas supply for the heating conductor is then not necessary.

Short description:

- Temperatures up to 1800 °C

- Atmospheres:

– Old construction: ambient atmosphere only

– New design: inert, oxidizing and reducing - Standard tube diameter up to 60 mm

- Heated length: 200 mm

- Control unit separated from furnace

- Fits through glovebox locks (outer diameter < 250 mm)

- Can be flanged to glovebox walls

- Power range up to approx. 3 kW

- Wall temperature below 40 °C (with cooling)

Heating system:

- Single-zoned

Equipment features:

- Vacuum pump with measuring device and inert gas dosing device for stand-alone operation

- Rack for furnace use in changing working positions

- Ampoule with a maximum inner diameter of 50 mm (for work in all atmospheres and vacuum)

- Lifting floor for easy loading from a glovebox from below

- Charging device for easy charging in a horizontal arrangement

- Sample basket for loading the top-loader version

- Rotating device for powder treatment at maximum temperatures

- Gas supply units

- Sample thermocouples

- Observation window

- Adapter flanges for easy mounting on glovebox walls

- Fibre channel for transporting fibres from a glove box through the furnace to the outside or into a second glove box

- Crucibles and boats

- Sample rack

- Wide range of control units with and without PC interfaces

- Software for program and gas control

Applications:

- Physical experiments

- Solid state chemical analyses

- Melting

- Calcination

- Pyrolysis

- Tempering of SiC wafers

- MOx Synthesis

- Sintering

- Vacuum tempering in ampoule

- Degassing

- Fibre treatment

Tube furnace type LOSiC

(Laboratory Oven/Furnace with SiC heating elements)

LOSiC describes a high-temperature tube furnace with SiC heating elements and working tube accessible from both sides, for temperatures up to 1500 °C with many equipment variants. It is preferably used at high temperatures for non-reducing atmosphere. The heating elements work in air.

Short description:

- Temperatures up to 1500 °C

- Atmospheres: all gases (depending on pipe material)

- Tube diameter: 50 to 200 mm

- Heated length up to 1200 mm

- Control unit separated from furnace

- Can be integrated in complex devices

- Power range up to maximum 10 kW

Heating system:

- Single-zoned

- Multi-zoned

Equipment features:

- Insert working tube with gas-tight end caps (for working also in oxygen-free atmospheres)

- Charging systems

- Sample thermocouples

- Observation window

- Frame for holding the furnace in different working positions

- Crucibles and boats

- Gas supply units

- Afterburner

- Weighing equipment

- Wide range of control units with and without PC interfaces

- Software for program and gas control

Applications:

- Melting

- Calcination

- Pyrolysis

- Vacuum tempering

- Debinding

- Sintering

- Degassing

- Crystal Growing

- Thermochromatography

- Gas chromatography

- Contact angle measurements

- Fibre treatment

- Quenching tests

- Investigation of reaction kinetics in downdraft

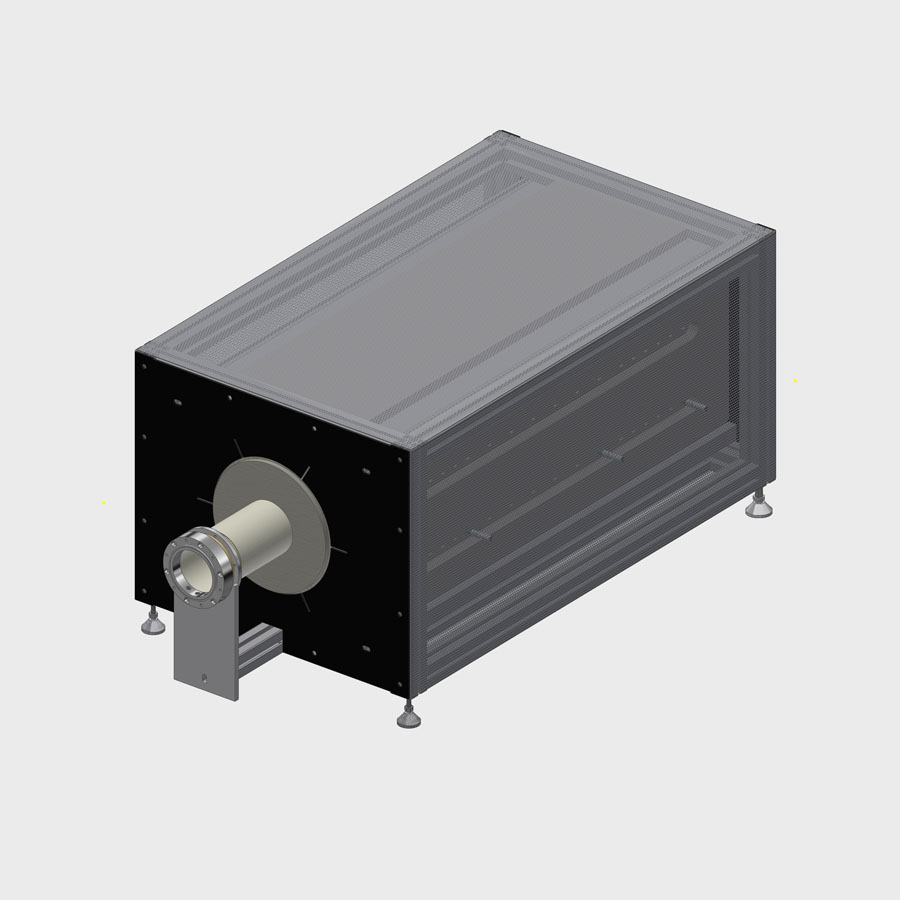

Tube furnace type LOMOS

(Laboratory Oven/Furnace with MOSi2 heating elements)

LOMOS is a high-temperature tube furnace with MoSi2 heating elements and a horizontal working tube accessible from both sides, for temperatures up to 1800 °C with many equipment variants. It is also preferably used at high temperatures for non-reducing atmospheres and its heating elements work in air.

Short description:

- Temperatures up to 1800 °C

- Atmospheres: all gases and vacuum (depending on pipe material)

- Tube diameter: 50 to 100 mm

- Heated length up to 1500 mm

- Can be integrated in complex devices

- Power range up to maximum 20 kW

Heating system:

- Single-zoned

- Multi-zoned

Equipment features:

- Insert working tube with gas-tight end caps (for working also in low-oxygen atmospheres)

- Charging systems

- Sample thermocouples

- Observation window

- Maximum temperature window for gas sensing elements (the transparent medium is at furnace temperature)

- Crucibles and boats

- Gas supply units

- Afterburner

- Wide range of control units with and without PC interfaces

- Software for program and gas control

Applications:

- Melting

- Calcination

- Pyrolysis

- Debinding

- Sintering

- Degassing

- Thermochromatography

- Gas chromatography

- Contact angle measurements

- Fibre treatment

- Vacuum tempering

LORA_S.Nr.:14-0-116

LOBA_S.Nr.:18-0-140

LORA_S.Nr.:18-0-083

LOSIC_S.Nr.:14-0-123

LOSA_S.Nr.:16-0-023

LOBA-Gradientenofen_S.Nr.:16-0-069

LOBA_S.Nr.:18-0-023

LOBA_S.Nr.:17-0-262

LORA-G-schwenkbar_S.Nr.:17-0-159

LOMOS_S.Nr.:17-0-033

LORA-G_S.Nr.:17-0-232